home > Management consulting > Operational Excellence > Lean production >

Realscheme's lean production consulting is a professional service that focuses on systematically eliminating waste, stabilizing quality, optimizing processes, enhancing efficiency, and creating value, achieving a leap in enterprise production efficiency through tool empowerment and cultural transformation. The Realscheme expert team helps enterprises establish an efficient, flexible and sustainable ultra-low production cost management system through systematic methodology, creatively combining the Toyota Production System (TPS) with modern digital management tools, providing full-process support from strategic planning to execution and implementation. Hers value is not only reflected in short-term cost savings but also more in building endogenous competitiveness that ADAPTS to the dynamic market. With the advent of the era of thin profits, Realscheme's unique lean production model has become the most effective mode for modern enterprises to deal with small-batch and multi-variety production.

The lean production (LP) independently created by Realscheme mainly focuses on systematically eliminating waste, enhancing efficiency, stabilizing quality, and optimizing processes. It combines the characteristics of multiple varieties, small batches, and complex processes in discrete industries such as packaging and printing, electronics, cables, and metal cutting. Generally, it includes the following core service components:

• Value stream analysis and waste identification;

• Assessment of the current situation of the production system;

• Integrated optimization of production planning and scheduling (such as APS advanced scheduling);

• Standardized operations and single-piece flow implementation;

• On-site 5S and visual management;

• Equipment preventive maintenance system (such as TPM Total Productive maintenance mechanism);

• Foolproof and error-proof system design;

• Pull-based supply chain design (such as VMI Vendor Managed Inventory and JIT distribution model);

• Logistics route optimization (such as unitized packaging and AGV transportation);

• IOT and data platform construction (such as MES and SCADA);

• The application of intelligent production scheduling algorithms solves the multi-constraint collaboration problem of equipment, personnel, materials in discrete manufacturing;

• Multi-skilled worker training system;

• Lean culture implantation, such as the improvement proposal system, A3 reporting, PDCA cycle, and continuous improvement CI mechanism, etc.

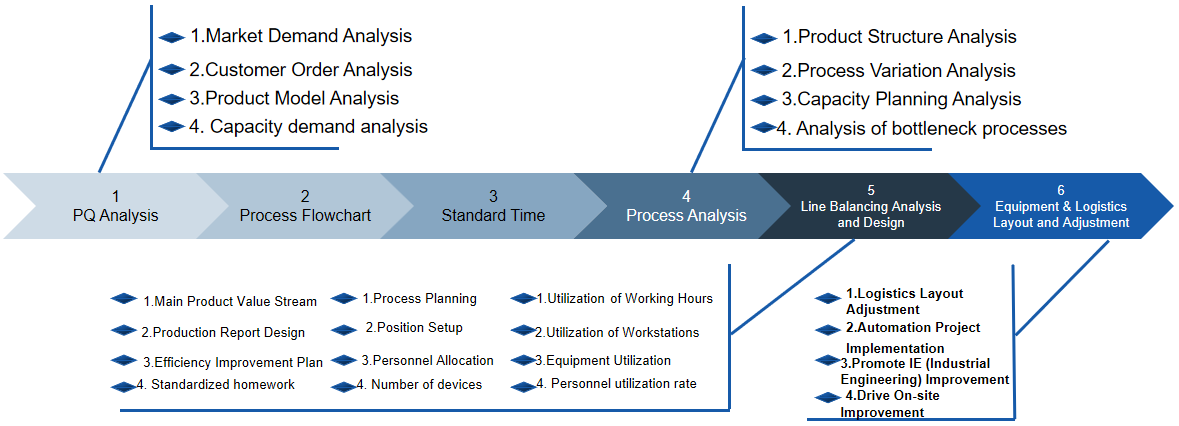

The methods and techniques of Realscheme lean production can be summarized as the following core framework, integrating phased implementation, tool application and systematic management principles. The core idea of Realscheme's lean production is to combine lean philosophy (eliminating waste) with industrial engineering (IE) tools to form a implementable enterprise transformation system.

Our methods and techniques include:

This is a promotional slogan