home > Management consulting > Operational Excellence > Lean Quality >

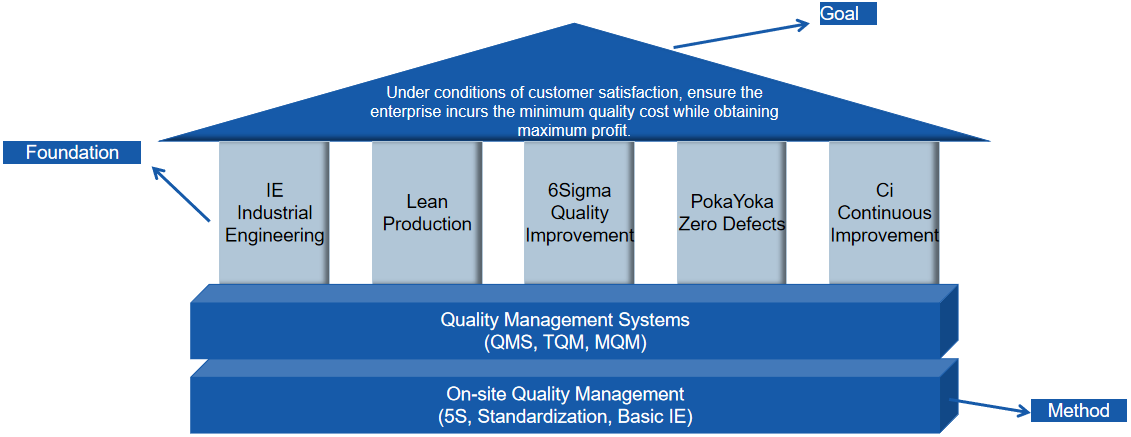

Realscheme believes that quality is the decisive battlefield for an enterprise's future competition. Quality is the life of an enterprise and also one of its core competitive capabilities. According to the data statistics and analysis of Realscheme over the years, the explicit cost of quality generally accounts for more than 25% of the total operating cost excluding materials, while its implicit cost is 3 to 4 times that of the explicit cost. The essence of Realscheme Lean Quality Consulting is the reconstruction of a quality ecosystem driven by data and based on customer demands, covering the entire chain from system design to digital implementation. It integrates lean concepts with Industry 4.0 technologies to achieve the predictability, traceability and controllability of quality issues. Achieve the continuous evolution of the enterprise's quality capabilities, reduce quality costs, and enhance customer satisfaction.

The quality management consulting for discrete manufacturing industries should be designed with service components based on their industry characteristics (such as multi-variety and small-batch production, complex product structures, and discrete process flows). When implementing specifically, modular service plans should be customized in combination with the enterprise scale and industry characteristics. The core services and components should include the following aspects:

• Standardized system design, covering the entire operation process;

• Diagnosis and improvement of process Defects;

• Personnel capability enhancement, quality awareness/Six Sigma Green Belt/Black Belt training;

• Supplier quality management to reduce the risks of raw materials;

• Construction of a material traceability system, combined with MES or LIMS systems to achieve full life cycle traceability of materials;

• Dynamic quality monitoring and early warning of abnormal fluctuations;

• Process parameter optimization, DOE verification, and reduction of line change debugging time and quality loss;

• Intelligentize the inspection process and design automated inspection plans (such as visual inspection and sensor feedback);

• Implementation of the Quality Management System (QMS), and customized deployment of systems such as LIMS and MES;

• Big data analysis and prediction;

• Quality cost analysis, accounting, identification, and formulation of improvement priorities;

• Closed-loop management of customer feedback.

Realscheme's quality management consulting is specifically designed for discrete manufacturing industries such as packaging and printing, electronics, metal cutting, and cables. It combines traditional tools with digital technologies to build a closed-loop system from data collection, process control to full-process traceability. In practical applications, enterprises can choose systems such as Q-DAS and SW-LIMS according to their needs, and adapt to management frameworks such as TQM or Six Sigma.

This is a promotional slogan