home > Management consulting > R&D Consulting > Intelligent Process Engineering (IPE) >

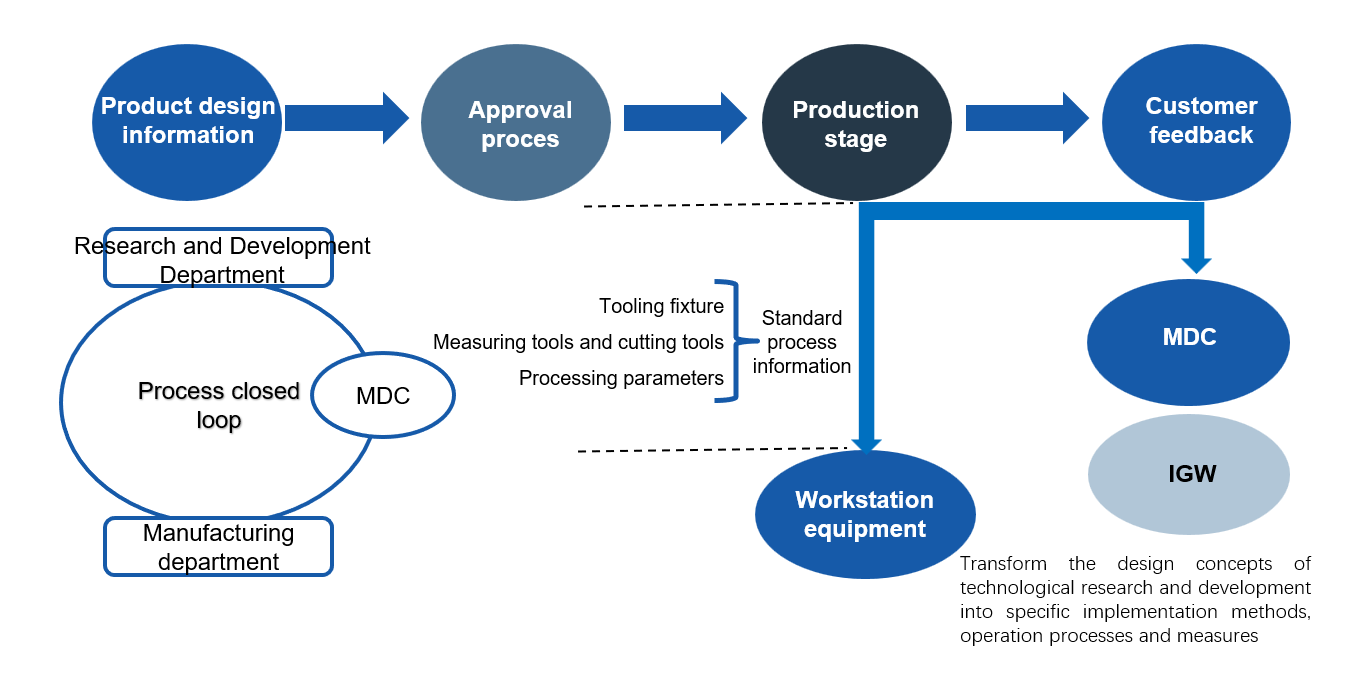

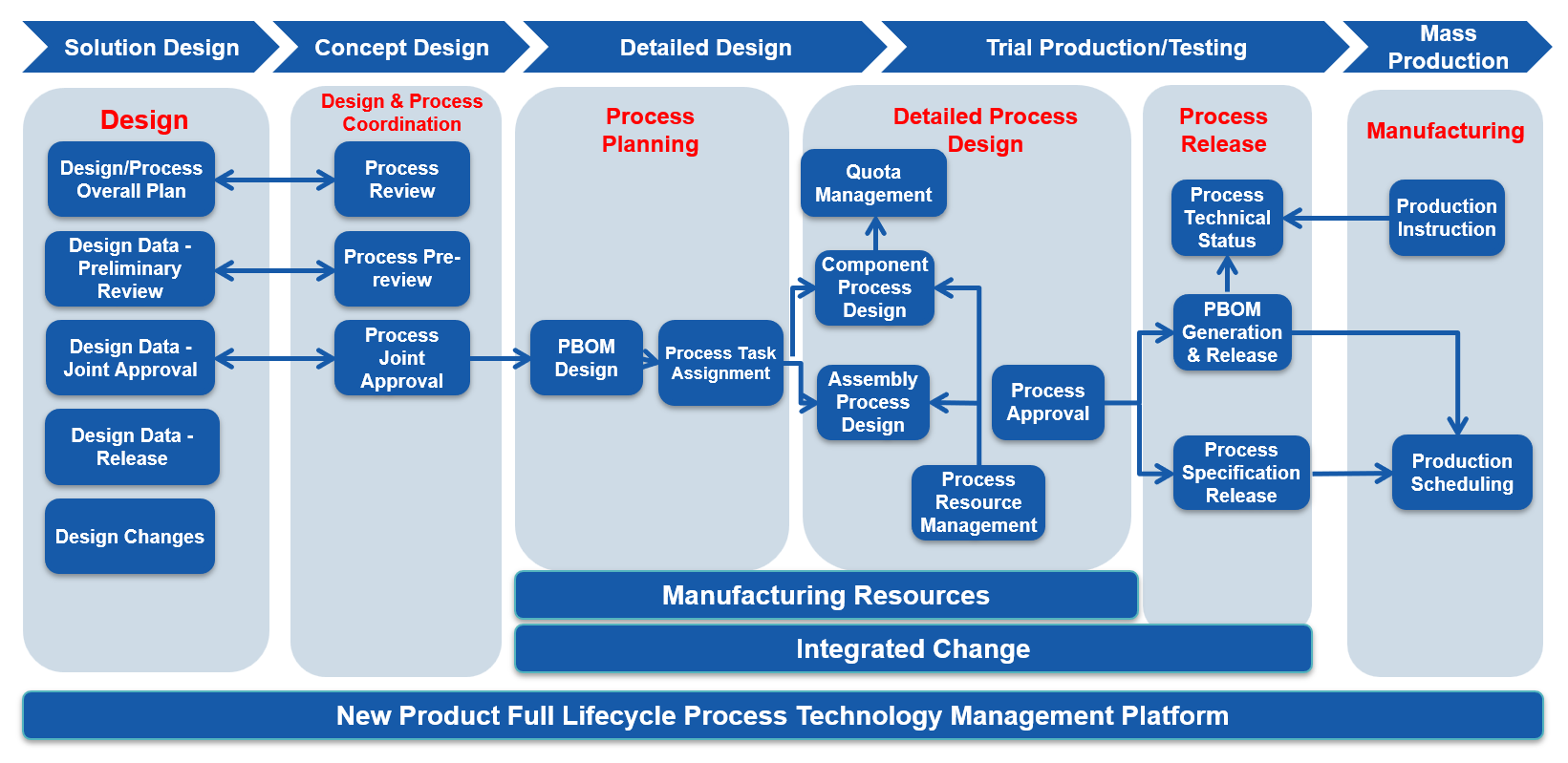

Realscheme's IPE (Intelligent Process Engineering) is a consulting service product designed and developed for discrete manufacturing enterprises. IPE's key idea is to focus on the characteristics of multiple varieties, small batches, and complex processes of discrete manufacturing enterprises (such as packaging, printing, clothing, cable, automotive, and other industries), and combine intelligent manufacturing technology to achieve full-process optimization of production, achieve the goals of stable product quality, improved production efficiency and cost savings in the process. IPE integrates data modeling, simulation optimization, real-time scheduling and an integrated system. The core lies in addressing the production challenges of multiple varieties and small batches through a balance between standardization and flexibility. IPE Consulting has comprehensive advantages in the depth of technology integration, the speed of policy response and the conversion rate of economic benefits. IPE is the most urgently needed consulting service direction for discrete manufacturing enterprises at present.

Realscheme has accumulated rich practical experience in Intelligent Process Engineering consulting. Realscheme has successfully guided many well-known enterprises to become outstanding benchmarks, helping them increase production efficiency by over 30% on average, raise the quality pass rate to over 98%, shorten the new product sample and trial production cycle by over 25%, and at the same time reduce the overall operating costs. The key components of the solution of Realscheme Intelligent Process Engineering are as follows:

• Enterprise current situation assessment;

• Structured and standardized process data;

• Production process optimization;

• Flexible production system design (modular process flow, introducing APS);

• Integrate PDM (Product Data Management), data governance and system interconnection;

• Full-process quality traceability and optimization of process parameters;

• SPC (Statistical Process Control);

• Refined cost accounting;

• Selection and integration of intelligent equipment;

• Intelligent production scheduling and dynamic dispatching;

• Intelligent transformation at the workshop level;

• Process simulation and parameter optimization;

• Pilot verification and risk control;

• Training and knowledge accumulation;

• Application for recognition and rewards of national, provincial or municipal intelligent factories or digital workshops;

• Continuous improvement mechanism.

When serving manufacturing enterprises, Realscheme Intelligent Process Engineering, based on the characteristics of discrete industries and in combination with modern technical means, mainly adopts the following tools and methods:

• Data management and modeling tools, such as PLM/PDM;

• Intelligent master data management system;

• Digital process design tools (CAD/CAM/CAE);

• Virtual debugging and Digital twin;

• Use 3D CAD/CAE software for product design and process simulation;

• Advanced Scheduling System (APS), combining MRP strategy and real-time data;

• Real-time data collection and Internet of Things (IoT);

• Intelligent detection and SPC analysis;

• A full-process traceability system for batch management and serial number tracking;

• Deep integration of MES and ERP;

• Big data analysis and AI algorithm optimization of process parameters (such as energy consumption and tool life);

• Lean production and standardization methods, such as Value Stream Analysis (VSM) and modular process design.

This is a promotional slogan